Taylor Clary is a fourth year Honors student from Wichita, Kansas, studying food science and nutrition. Last spring, she began conducting research through the Department of Food Science on combating food waste using 3D printed vegetable snacks. Taylor’s ongoing project utilizes “imperfect” or “ugly” produce to cut down on food loss, and will ultimately be her honors thesis.

Why did you get involved in researching food waste? I’ve always felt a draw towards researching sustainability and food waste, especially because of my major in food science. Dr. Ali Ubeyitogullari, my faculty advisor, also presented the idea to work on combating food waste when we were touring his lab, and he mentioned that another student had been doing research working with corn husks, which is what originally led into this project. We worked together to develop the idea of using vegetables and fruits since so many of those go to waste every year because they aren’t seen as something that can be put in stores. We ultimately decided that converting imperfect vegetables into shelf-stable healthy snacks using a 3D printing would be a good way to reduce food waste.

Why is so much food waste produced? Because some food isn’t seen as perfect, or at times there might also be a quality issue. There’s a ridiculous amount of ugly or imperfect fruits and vegetables that isn’t seen as something that can be put onto shelves and sold. If a fruit or vegetable doesn’t look as pretty, producers don’t want to sell it because they know it won’t get picked. Also, it might go bad waiting so long on the shelves and potentially cause other produce to begin rotting sooner as well. Most of the time, though, the imperfect produce that we’re dealing with doesn’t have any microbial risk or anything, which is why we used it.

How did you come to 3D printing as a potential solution for food waste? When I was first touring Dr. Ali’s lab he had a couple different 3D printers on hand, and that seemed like a novel idea to me. I thought that if we could basically reduce vegetables down to a form that nobody sees, they won’t know what imperfections are there. Then, you just recreate something, which adds another aspect of the whole project, and that snack can have a cool shape or a design.

In this project, an extrusion-based 3D food printer is being used. A robotic arm moves along a surface with a cylindrical cartridge to dispense food paste. There are certain parameters we had to consider when developing this food paste, including its ability to be extruded through the nozzle, to have a sufficient viscosity for layers to stack, and then the shape of the final product due to the food paste’s stability and definition. Determining a formulation that met all these parameters was time-consuming.

What do 3D printed snacks taste like? We unfortunately can’t taste the snacks yet because we’ve been working in a non-kitchen lab. Eventually, we’d like to move the 3D printer into a kitchen safe lab so that we can try the snacks to see what they taste like. I imagine they’re similar to the cauliflower mashed potatoes people are using in order to lean away from potatoes, except we’re using broccoli with flour.

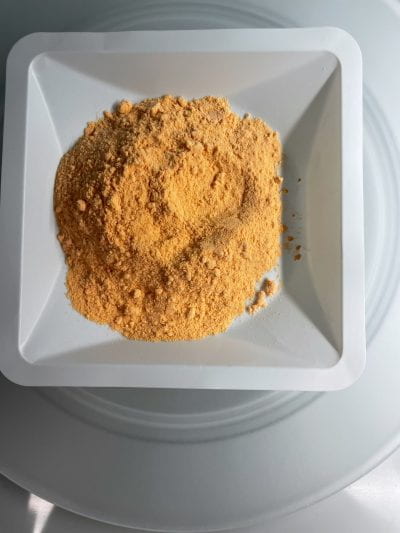

We’re currently working with broccoli and carrots to make the snacks. First, we freeze-dry the produce and then grind it down into a powder where you don’t see imperfections. Also, the shelf life of the product is extended pretty much indefinitely after it’s freeze-dried, and that makes it easier to have a constant stash of it we can just put it into a paste. We have two different formulas we’re doing: flour and then potato flour, which would be a gluten-free product. We’re doing different variations of either broccoli, carrot or a broccoli-carrot mixture, and then adding salt, olive oil and water. It’s pretty low ingredient. We also bake it after as well so that it’s more like a cracker.

Did this experience change your post-college plans? I think it has given me a better glimpse into the work that I will be doing in the food industry after college. When I graduate, I will be working as a quality assurance team advisor trainee for Schreiber Foods. I feel more comfortable and knowledgeable about the lab equipment that I will encounter. However, I do still want to pursue research and development after getting a master’s degree, and I really think that this project has helped me learn more about the whole process of research and development. Especially, the patience required when starting over on formulations when they don’t work and perfecting a process.