Ali McAtee is an honors college fellow in the College of Engineering studying chemical engineering. She and her research team were featured on a Planet Forward Earth Day special for their work with algae and butanol fuel. Ali received honorable mention from the Barry Goldwater Scholarship Foundation.

During the summer and fall semesters of 2010, I performed research in the chemical engineering department under my advisor, Dr. Jamie Hestekin. The overall goal of the research group is to use algae to produce fuel-grade butanol. My specific goal is to implement hollow fiber membranes into the algae growth systems in order to promote growth. Hollow fiber membranes used to pump carbon dioxide to the algae will increase carbon dioxide concentrations in the water as well as gas levels reaching the algae and, in doing so, increase the algae’s growth rate. By substantially increasing the algae’s growth rate, the amount of butanol able to be produced from the algae’s lipid content is drastically increased.

During the summer and fall semesters of 2010, I performed research in the chemical engineering department under my advisor, Dr. Jamie Hestekin. The overall goal of the research group is to use algae to produce fuel-grade butanol. My specific goal is to implement hollow fiber membranes into the algae growth systems in order to promote growth. Hollow fiber membranes used to pump carbon dioxide to the algae will increase carbon dioxide concentrations in the water as well as gas levels reaching the algae and, in doing so, increase the algae’s growth rate. By substantially increasing the algae’s growth rate, the amount of butanol able to be produced from the algae’s lipid content is drastically increased.

I had just returned from a semester abroad at the beginning of the summer of 2010 grant period and spent about a week getting completely caught up on the laboratory algae growth system and on what advances had been made in my absence. I ran chemical assays on the water we used in the system to determine starting levels of carbon dioxide, organics, and other important qualities. The water being used is from a local creek—the same creek the algae being used was removed from.

Along with water tests, fertilizers were also tested. These systems are proposed to be used in runoff streams from croplands heavy in fertilizers; therefore, it is logical to test different fertilizers for qualities that would impact algae growth. The water with each fertilizer dissolved in it was also tested and compared to the beginning, clean creek water as was the growth of the algae with different fertilizers being used.

Along with the water/fertilizer tests, bundles of hollow fiber membranes were constructed and placed in the system. Growth tests showed some increase in growth with the fibers, however significant damage was being done to the fibers when the algae was harvested via vacuum suction. Since harvesting was taking place weekly and fibers are not cheaply attained, the problem was significant.

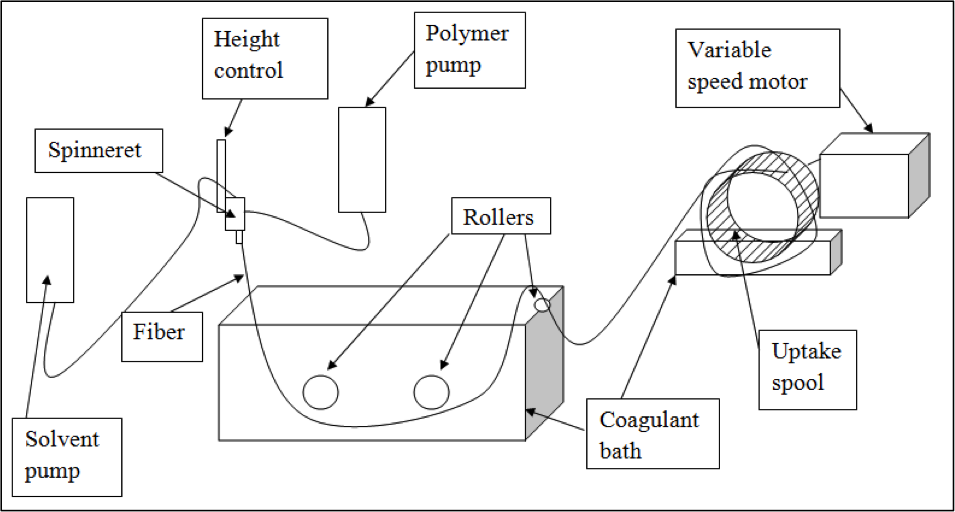

Dr. Hestekin proposed that we begin spinning membranes of our own to determine if the strength of the fibers could be manipulated and increased. Through this new idea, Dr. Hestekin and I travelled to The National University of Singapore in Singapore during August of 2010 to visit Dr. Neil Chung, a world renowned hollow fiber membrane expert. During this trip to Singapore, I was able to spend a significant time in Dr. Chung’s laboratories with his graduate students and was taught all about hollow fiber membrane structure and production—also referred to as “spinning.” The students there demonstrated how to spin membranes, the important features of a spinning apparatus as well as different manipulations of said apparatus that would change membrane composition, structure, porosity, thickness, and numerous other qualities. As a gift, Dr. Chung gave me and Dr. Hestekin a spinneret—the piece of the apparatus that is most crucial by separating the polymer and solvent solution, creating the hollow membrane structure. Through this trip, Dr. Hestekin arranged for me to give part of his presentation there over my specific application of hollow fiber membranes here at the University of Arkansas. I feel very honored to have been given this opportunity to present to world leading experts in my field.

During the fall grant term, I designed the spinning apparatus that would be constructed in our laboratory in place of our algae growth system. The algae growth system was scaled up and moved to a greenhouse in order to get more accurate growth measurements. The designing of the apparatus took several months of the fall grant term because considerations had to be taken to remain within our limited budget. The system in Singapore was an elaborate, more automated system that our budgets would not permit. Below is a diagram of our system as I designed it. Also during the fall semester, the apparatus’ design specifications were set and materials ordered for construction.

Diagram of hollow fiber membrane spinning apparatus for implementation in University of Arkansas laboratory. Designed by: Ali McAtee

Through this Honors College Research Grant, I have been able to realize my passion for travelling around the world learning from experts in fields of interest to me. Also, I have been able to complete a project to scale up on campus and begin a new focus on the same project on my own. The membrane spinning will be predominately my project and will not necessarily have a graduate student assigned to me to watch over me and I will be able to freely explore and research on my own. Also, through this experience, I have successfully designed a system and will see it brought to life during the next semesters, of which I feel very proud.